Completed Research Projects

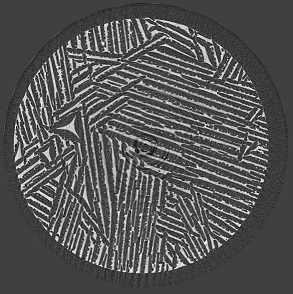

Creep of Thermoelectric Materials

Muath Mohammed Al Malki, co-advised by Prof. Jeffrey Snyder

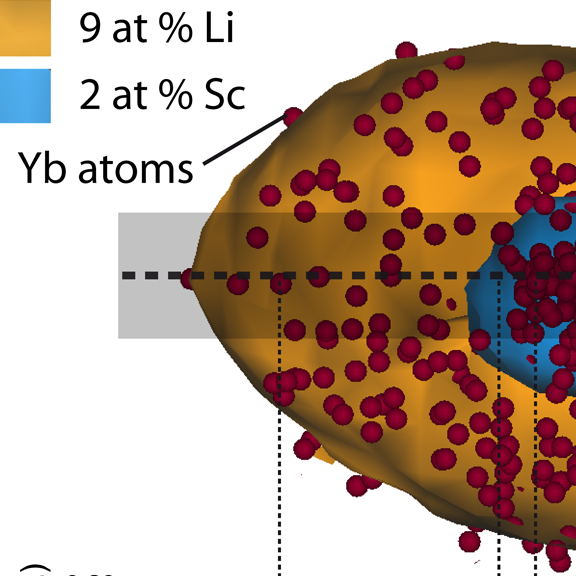

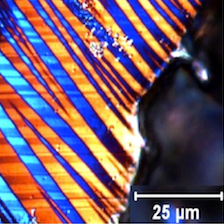

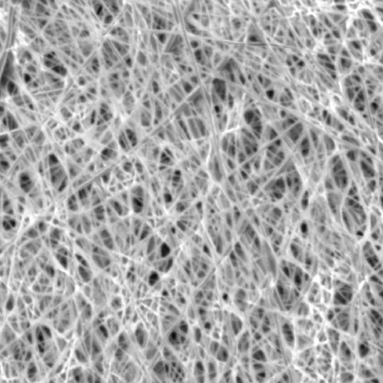

We are exploring the relationship between creep deformation (during operation at stress and temperature) and thermoelectric performance degradation for various thermoelectric alloys.

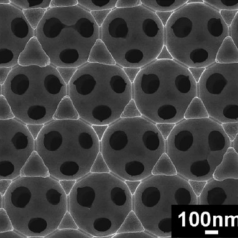

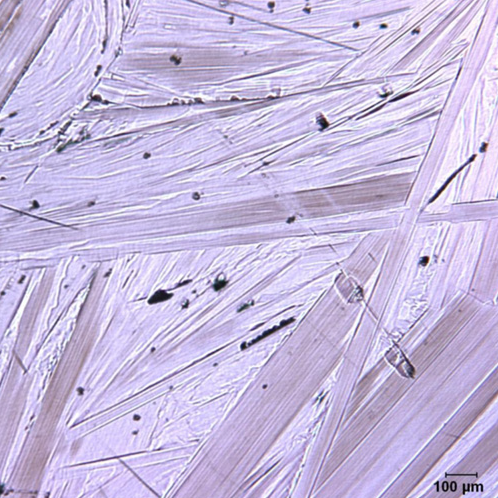

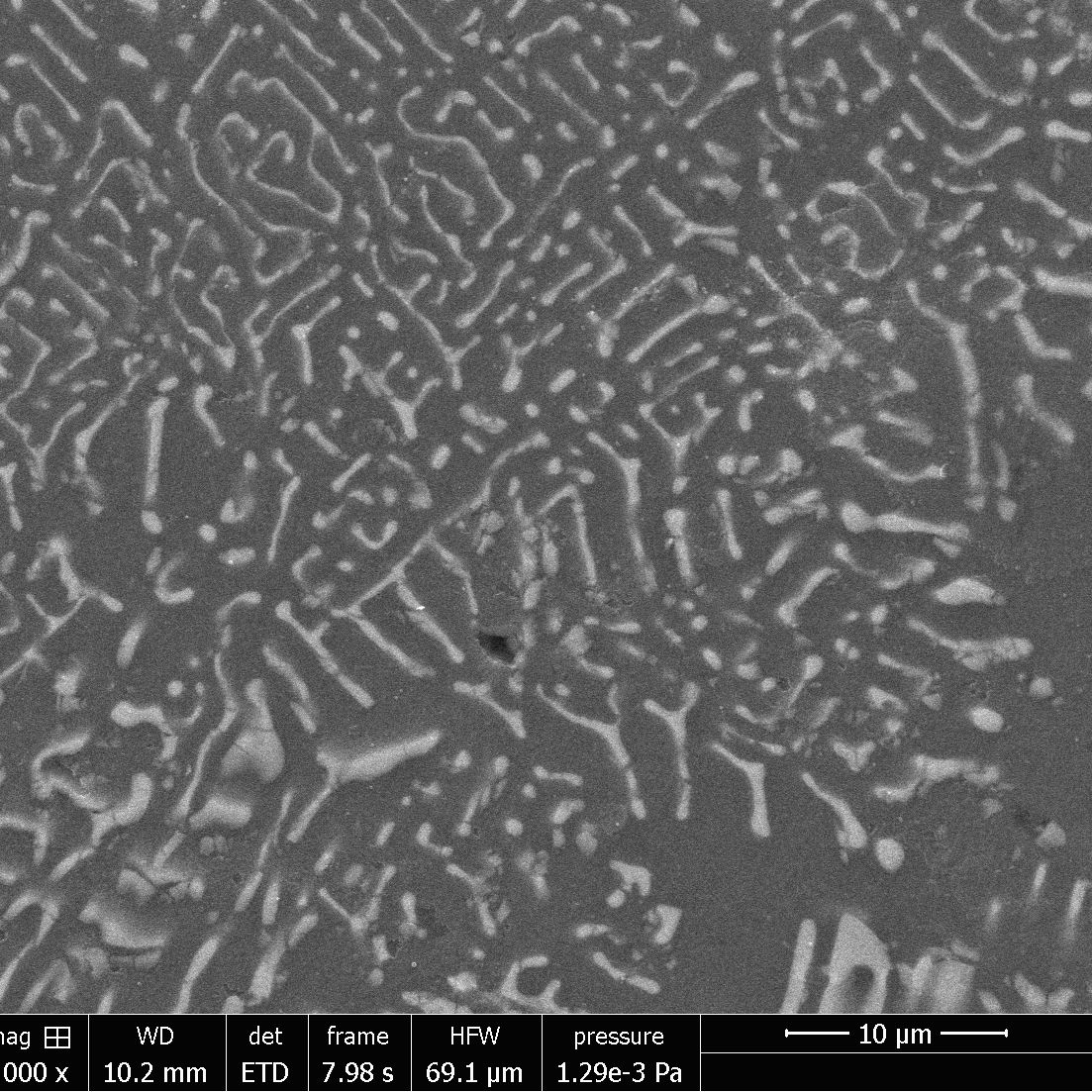

Cast Al-Ce based Eutectic Alloys with High Creep Resistance

Tiffany Wu, *Yang Liu and *Daniel Ng, co-advised by Dr. Alex Plotkowski, Dr.Amit Shyam, and Dr. Ryan Dehoff, Oak Ridge National Laboratory

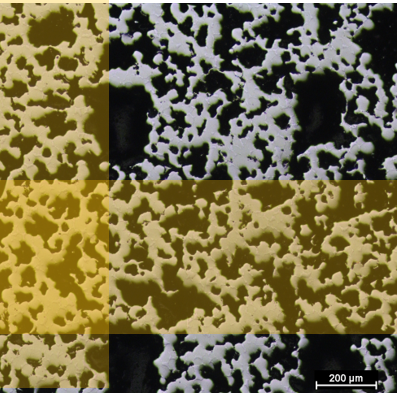

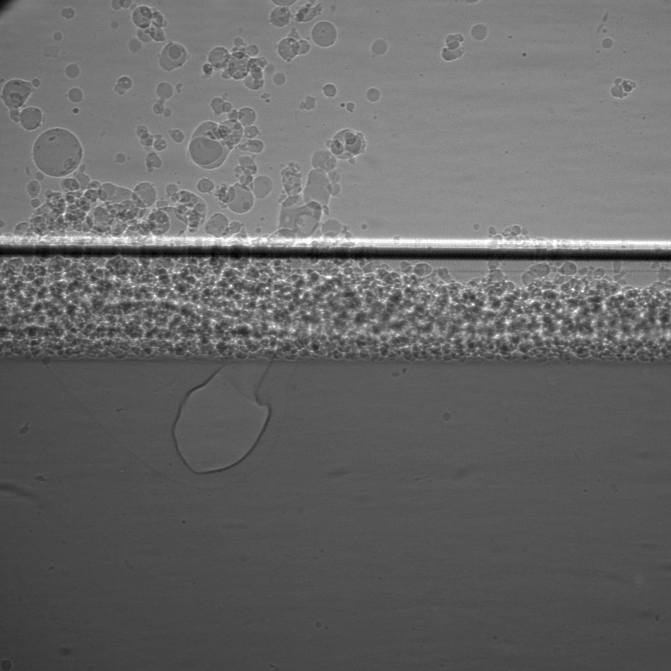

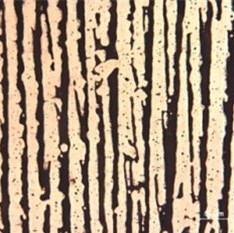

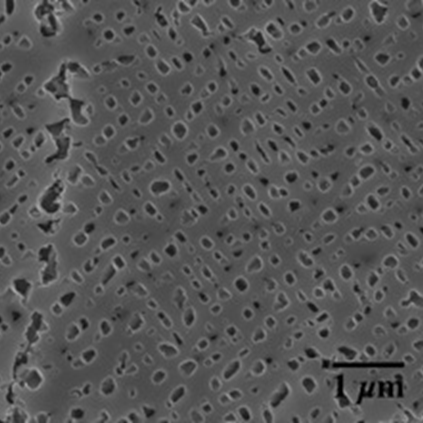

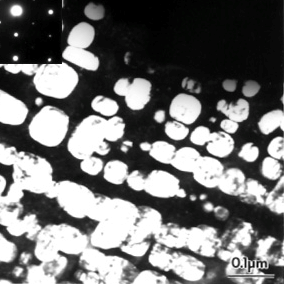

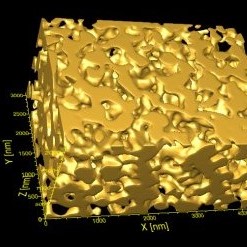

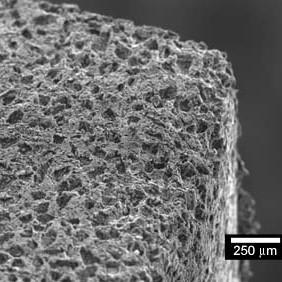

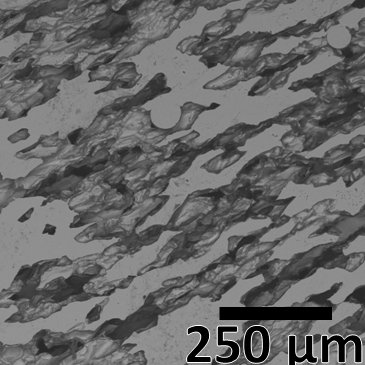

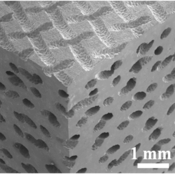

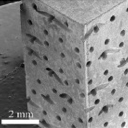

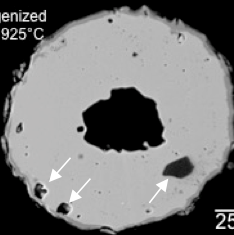

Our work involves microstructural investigations and compression creep testing of Al-Ce binary alloys, with the goal of studying how Ce additions may be utilized to develop alloys with enhanced creep resistance.