Cobalt-based Superalloys

Brandon Ohl, *Dr. Fei Xue, *Dr. Jacques Perrin Toinin, *Ding-Wen Chung, *Dr. Fernando Reyes, *Francesca Long, *Chunan Li, *Hyeji Park, *Dr. James Coakley, *Dr. Peter Bocchini, and *Dr. Daniel Sauza

*researcher graduated/completed assignment

Designing Novel Nanoscale Precipitate Strengthened Cobalt-based Superalloys

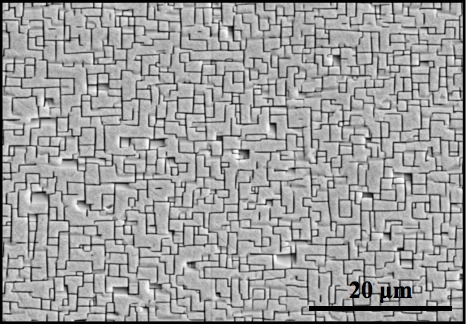

High temperature, high strength alloys have been studied for many years and have lead to significant improvements in aerospace engines, as well as in the nuclear and fossil fuel electric power industries. Ni-based superalloys have been the predominant material of choice for these applications due to their ability to operate at 90% of their melting temperature and capacity to withstand high mechanical stresses under harsh environments. The Ni-based superalloys gain their unique properties through the formation of a γ-γ` microstructure which consists of cuboidal L12 precipitates in an f.c.c. matrix. It was recently discovered that Co-based alloys could be processed to have the same γ-γ` as the more widely used Ni superalloys.

The significance of this discovery is that the initial cobalt superalloys have been shown to have solidus temperatures 100-150 ºC higher than optimized Ni superalloys. Higher operation temperatures could have a potentially enormous effect in the electric power production industry. Taking into account ideal thermodynamic efficiency parameters of a heat engine (the Carnot Efficiency), once can see that efficiency is directly proportional to increased operating temperatures. Higher efficiencies in power production will in turn decrease the amount of fuel consumed which will reduce the quantity of greenhouse gases released. Lower rates of pollution resulting from higher operating efficiency would have a positive effect on the environment that would also lead to financial savings by reducing the amount of fuel used as well as increase public health by lessening the amount of air and water pollution.

In addition to higher temperature capabilities, the Co-based superalloys improve upon Ni in several other ways. Preliminary studies have shown that it is likely that Co superalloys can be processed into large single crystals (a form needed to achieve good high temperature creep resistance) without forming solidification defects on their surface (so-called freckles) that plague Ni-based superalloys

Related Publications

- Tirado, Fernando L. Reyes, and David C. Dunand. "Increasing γ'volume fraction in Co-Nb-V-and Co-Ta-V-based superalloys." Journal of Materials Research and Technology 11 (2021): 2305-2313.

- Li, C., Chung, D. W., Dunand, D. C., & Seidman, D. N. (2020). Microstructural stability and mechanical behavior of a Co-20Ni-7Al-7W-4Ti at.% superalloy. Journal of Alloys and Compounds, 848, 156378.

- Long, F. R., Baik, S. I., Chung, D. W., Xue, F., Lass, E. A., Seidman, D. N., & Dunand, D. C. (2020). Microstructure and creep performance of a multicomponent co-based L12-ordered intermetallic alloy. Acta Materialia, 196, 396-408.

- Chung, Ding-Wen, Daniel S. Ng, and David C. Dunand. "Influence of γ'-raft orientation on creep resistance of monocrystalline Co-based superalloys." Materialia 12 (2020): 100678.

- Chung, D. W., Toinin, J. P., Lass, E. A., Seidman, D. N., & Dunand, D. C. (2020). Effects of Cr on the properties of multicomponent cobalt-based superalloys with ultra high γ'volume fraction. Journal of Alloys and Compounds, 832, 154790.

- Tirado, Fernando L. Reyes, Spencer V. Taylor, and David C. Dunand. "Low-density, W-free Co-Nb-V-Al-based superalloys with γ/γ'microstructure." Materials Science and Engineering: A 796 (2020): 139977.

- Ng, D. S., Chung, D. W., Toinin, J. P., Seidman, D. N., Dunand, D. C., & Lass, E. A. (2020). Effect of Cr additions on a γ+ γ'microstructure and creep behavior of a Co-based superalloy with low W content. Materials Science and Engineering: A, 778, 139108.

- Tirado, Fernando L. Reyes, Spencer Taylor, and David C. Dunand. "Effect of Al, Ti and Cr additions on the γ-γ'microstructure of W-free Co-Ta-V-Based superalloys." Acta Materialia 172 (2019): 44-54.

- Tirado, Fernando L. Reyes, Jacques Perrin Toinin, and David C. Dunand. "γ+ γ' microstructures in the Co-Ta-V and Co-Nb-V ternary systems." Acta Materialia 151 (2018): 137-148.

- Coakley, J. et al. Rafting and elastoplastic deformation of superalloys studied by neutron diffraction. Scripta Materialia 134, 110–114 (2017)

- Bocchini, P. J., Sudbrack, C. K., Noebe, R. D., Dunand, D. C. & Seidman, D. N. Author’s Effects of Titanium Substitutions for Aluminum and Tungsten in Co-10Ni-9Al-9W (at. %) Superalloys. Materials Science & Engineering A 1–47 (2017). doi:10.1016/j.msea.2017.08.0347)

- Coakley, J., Lass, E. A., Ma, D., Frost, M. & Stone, H. J. Lattice parameter misfit evolution during creep of a cobalt- based superalloy single crystal with cuboidal and rafted gamma-prime microstructures. Acta Materialia (2017). doi:10.1016/j.actamat.2017.06.025

- Sauza, D. J., Bocchini, P. J., Dunand, D. C. & Seidman, D. N. Influence of ruthenium on microstructural evolution in a model Co Al W superalloy. Acta Materialia (2016). doi:10.1016/j.actamat.2016.07.014

- Liu, Q., Coakley, J., Seidman, D. N. & Dunand, D. C. Precipitate Evolution and Creep Behavior of a W-Free Co-based Superalloy. Metallurgical and Materials … 47, 6090–6096 (2016)

Funding support

- CHiMaD: Center for Hierarchical Materials Design