Redox Cycling of Fe/FeO Microstructures

Stephen Wilke, Jacob Mack, and *Pedro Javier Lloreda Juardo,

Our group has used freeze casting to prepare highly porous foams of numerous metals, including copper [2,3], nickel [4], cobalt [5], tungsten [6], and iron [7,8]. Freeze casting typically requires suspensions containing submicron or nanometric particles to ensure suspension stability, but these sizes of particles are not practical for metals due to their high propensity for surface oxidation. Instead, we freeze-cast foams of the corresponding metal oxides and then reduce and sinter the oxide green bodies under H2 gas.

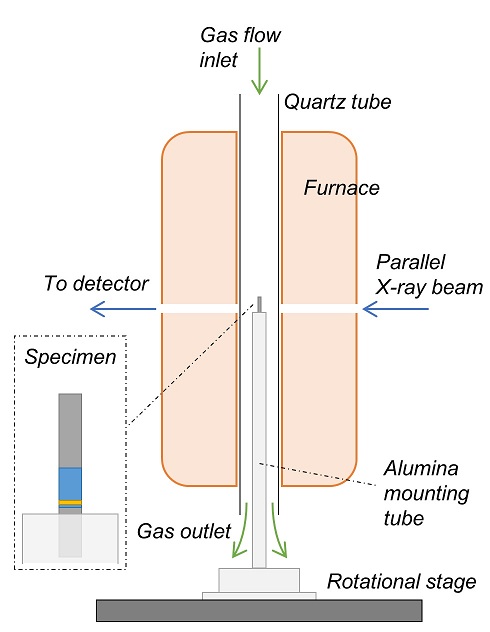

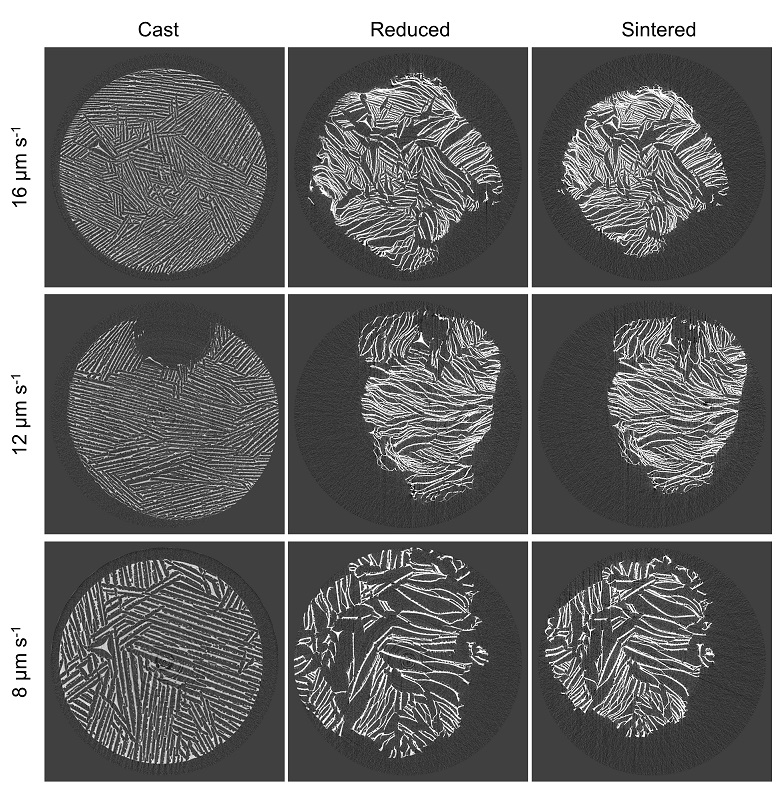

This reduction and sintering step results in large structural changes in the green body, due to volume contraction associated with the reduction transformation and densification during sintering [9]. We are using in situ X-ray microtomography to observe this structural evolution in foams created with various pore sizes and total porosity, to better understand the processing-structure relationships for metal foams created via freeze casting.

Fig. 1. Schematic of in situ X-ray tomography experimental setup. (Reproduced from [1].)

Fig. 2. Cross-sections of Fe2O3 freeze-cast foam green bodies prepared with different solidification velocities (8, 12, 16 μm s-1). These cross-sections are reconstructed from in situ tomography: as-cast, after reduction by H2 at 725 °C, and after sintering at 900 °C.

Related Publications

- S.K. Wilke, D.C. Dunand, In Operando Tomography Reveals Degradation Mechanisms in Lamellar Iron Foams during Redox Cycling at 800oC, J. Power Sources. 448 (2020) 227463.

- H. Park, M. Choi, H. Choe, D.C. Dunand, Microstructure and compressive behavior of ice-templated copper foams with directional , lamellar pores Department of Materials Science and Engineering , Northwestern University , 2220 Campus, Mater. Sci. Eng. A. 679 (2017) 435-445. doi:10.1016/j.msea.2016.10.057.

- A.I.C. Ramos, D.C. Dunand, Preparation and Characterization of Directionally Freeze-cast Copper Foams, Metals (Basel). 2 (2012) 265-273. doi:10.3390/met2030265.

- H. Jo, M.J. Kim, H. Choi, Y.-E. Sung, H. Choe, D.C. Dunand, Morphological Study of Directionally Freeze-Cast Nickel Foams, Metall. Mater. Trans. E. 3 (2016) 46-54. doi:10.1007/s40553-016-0068-y.

- H. Park, H.-H. Cho, K. Kim, K. Hong, J.-H. Kim, H. Choe, D.C. Dunand, Surface-Oxidized, Freeze-Cast Cobalt Foams: Microstructure, Mechanical Properties and Electrochemical Performance, Acta Mater. 142 (2018) 213-225. doi:10.1016/j.actamat.2017.09.066.

- A. Röthlisberger, S. Häberli, R. Spolenak, D.C. Dunand, Synthesis, structure and mechanical properties of ice-templated tungsten foams, J. Mater. Res. 31 (2016) 753-764. doi:10.1557/jmr.2016.62.

- A.A. Plunk, D.C. Dunand, Iron foams created by directional freeze casting of iron oxide, reduction and sintering, Mater. Lett. 191 (2017) 112-115. doi:10.1016/j.matlet.2016.12.104.

- R. Sepúlveda, A.A. Plunk, D.C. Dunand, Microstructure of Fe2O3 scaffolds created by freeze-casting and sintering, Mater. Lett. 142 (2015) 56-59. doi:10.1016/j.matlet.2014.11.155.

- A. Lichtner, D. Roussel, D. Röhrens, D. Jauffres, J. Villanova, C.L. Martin, R.K. Bordia, Anisotropic sintering behavior of freeze-cast ceramics by optical dilatometry and discrete-element simulations, Acta Mater. (2018). doi:10.1016/j.actamat.2018.06.001.

Funding support

- NSF