Cast Al-Ce based Eutectic Alloys with High Creep Resistance

Tiffany Wu ,*Yang Liu, and *Daniel Ng,

co-advised with Dr. Alex Plotkowski, Dr.Amit Shyam, and Dr. Ryan Dehoff, Oak Ridge National Laboratory

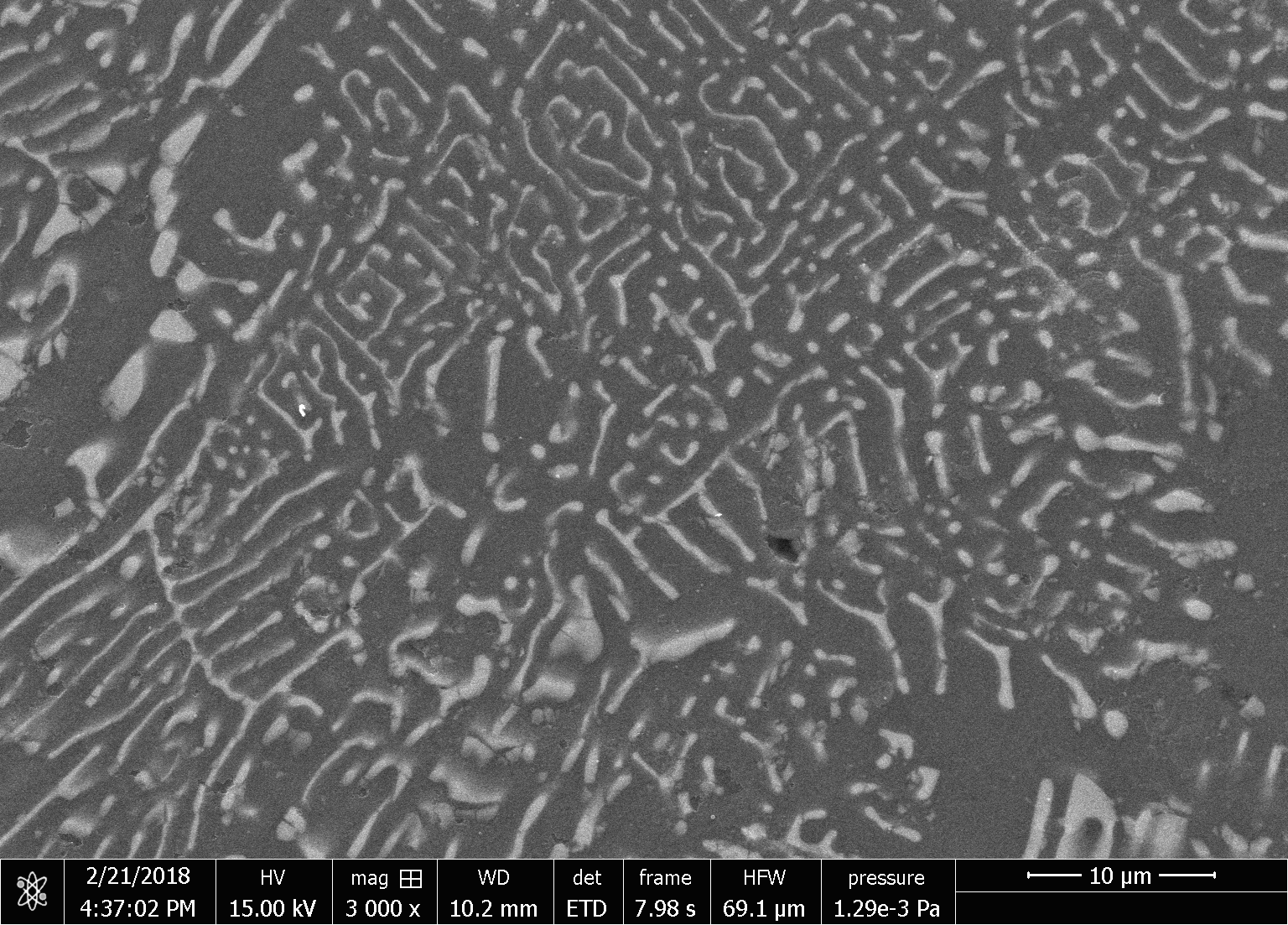

Previous studies on Al-Ce-Mg alloys have demonstrated thermal stability of Ce-rich eutectic strengthening phases up to 540°C. These results show promise for the development of Al-Ce alloys which maintain their strength at elevated temperatures. Our work involves microstructural investigations and compression creep testing of Al-Ce binary alloys, with the goal of studying how Ce additions may be utilized to develop alloys with enhanced creep resistance. Initial microstructural investigations have revealed a coarse grain structure with millimeter-scale grains expected to be resistant to diffusional creep. In addition, we observe a fine dispersion of eutectic Ce-rich phases which provide strength to the alloy. During compression creep testing at 300°C, we have observed creep deformation at lower rates and higher stresses than those of Er-free L12 -strengthened alloys extensively studied in our group, suggesting that Ce-additions may be used in developing the next generation of creep-resistant aluminum alloys.

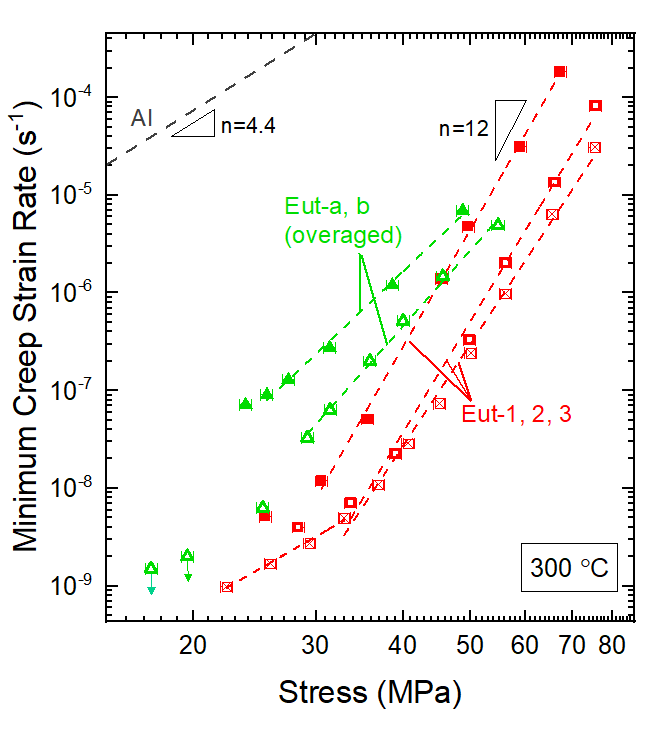

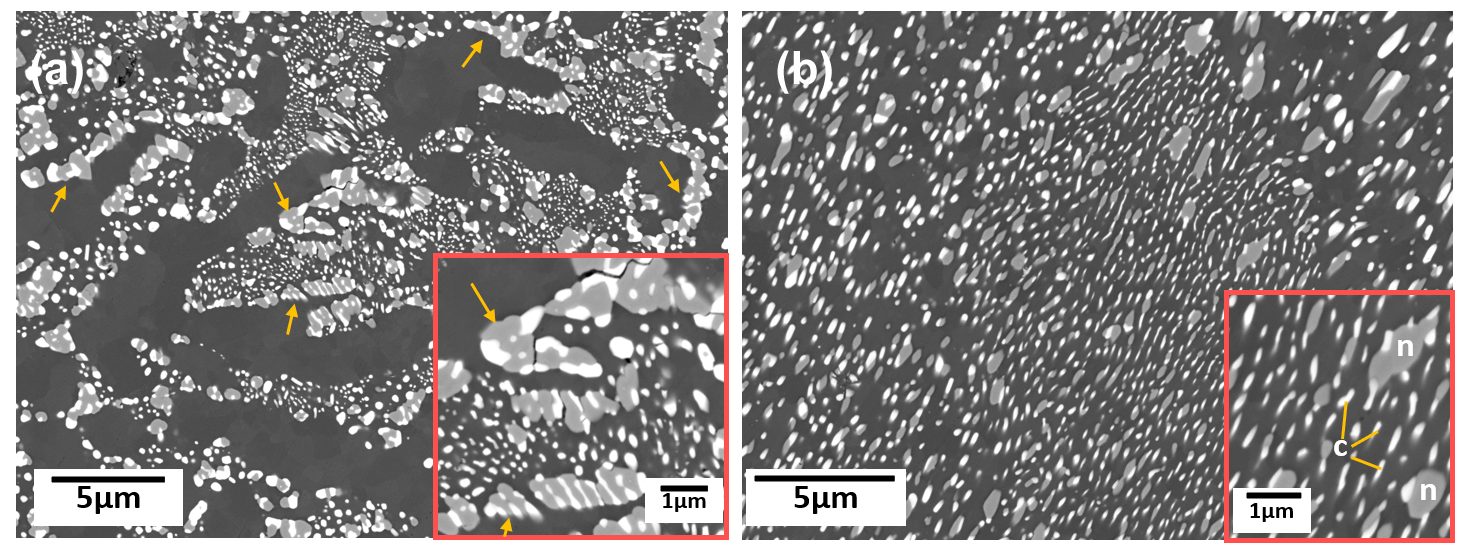

With promising creep- and coarsening resistance, the two binary eutectic systems, Al-Ni and Al-Ce, are combined into a ternary Al-Ce-Ni eutectics. Microhardness and microstructure evolution demonstrate excellent coarsening up to 425°C, with a gradual decrease in microhardness over long times. The sub-micron eutectic Al11Ce3 phase shows superior thermal stability and maintain its submicron fiber morphology, whereas the sub-micron eutectic Al3Ni rods coarsen faster into equiaxed micron-size precipitates. Creep resistance of as-cast eutectic Al-Ce-Ni at 300°C is comparable with binary eutectic Al-Ni and higher than binary eutectic Al-Ce. Overaged samples show higher creep rates than as-cast states due to their coarsened microstructures, but retains significant creep resistance, implying that load transfer is an important strengthening mechanism.

SEM image of Al-16Ce alloy, showing the euctic region

Double-logarithmic plot of minimum creep strain rate vs. stress, with best-fit lines drawn, at 300°C, for as-cast Eut (Al-10Ce-Ni) and Eut overaged at 590 °C for 24 h prior to creep.

BSE micrographs of cast Al-10Ce-5Ni aged at 400 °C for 1050 h showing phases (dark: Al, grey: Al3Ni and white: Al11Ce3). (a) hypoeutectic region, with coarsened Al3Ni and Al11Ce3 in eutectic colonies and, in a more pronounced manner, at interface between primary Al dendrites and eutectic regions (arrows). Higher-magnification insert highlights with arrow an example of Al3Ni engulfing Al11Ce3; (b) eutectic region, showing clearly coarsened Al3Ni precipitates and barely coarsened Al11Ce3 fibers (see higher magnification insert)

Related Publications

- T. Wu, A. Plotkowski, A. Shyam, D.C. Dunand, Microstructure and creep properties of cast near-eutectic Al-Ce-Ni alloys, Materials Science and Engineering: A. 833 (2022) 142551. https://doi.org/10.1016/j.msea.2021.142551.

- Y. Liu, R. A. Michi, and D. C. Dunand, "Cast near-eutectic Al-12.5 wt.% Ce alloy with high coarsening and creep resistance," Materials Science and Engineering: A, vol. 767, p. 138440, Nov. 2019, doi: 10.1016/j.msea.2019.138440.

- D. S. Ng and D. C. Dunand, "Coarsening- and Creep-Resistant Cast Hypoeutectic Al-Ce-Mg Alloy," SSRN Journal, 2019, doi: 10.2139/ssrn.3485043.

- Sims, Z. C., Rios, O. R., Weiss, D., Turchi, P. E., Perron, A., Lee, J. R., ... & An, K. (2017). High performance aluminum–cerium alloys for high-temperature applications. Materials Horizons, 4(6), 1070-1078.

Funding support

- Oak Ridge National Laboratory