|

While hydrogen is an excellent carrier of energy for solid oxide fuel cells, its storage is expensive and dangerous. By utilizing the steam/hydrogen redox reactions of iron/iron oxide and a fuel cell, a proof-of-concept of a novel redox flow battery with a very high energy capacity of 348 Wh/kg-Fe (approximately twice that of the best lithium ion batteries) was recently reported by Xu et al. This battery, however, contains a powder bed of loose iron/iron oxide which sinters over multiple redox cycles, resulting in a loss of hydrogen storage/production capacity. The freeze-casting technique, long used to create ceramic foams (Deville), has been adapted by the Dunand group to create metallic foams of titanium, nickel, copper and cobalt. By freeze-casting metal oxide powders and subsequent reduction and sintering, full metal foams are created. This project is to develop directional freeze-casting to create iron foams with elongated, interconnected channels as well as high microporosity for the use in iron-air batteries. The porous scaffold architecture will mitigate the degradation (e.g., sintering, fracture, surface area loss) resulting from with the large volume changes occurring during the redox cycles. |

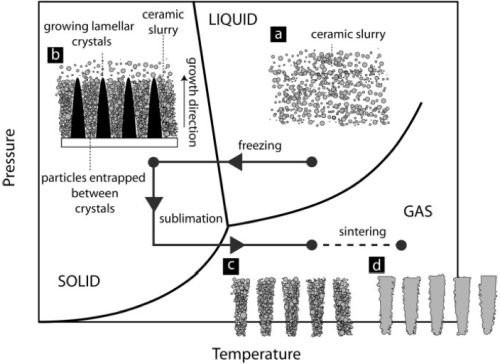

Figure 1. Deville Phase-diagram: Phase diagram of water showing the schematic process of freeze-casting. |

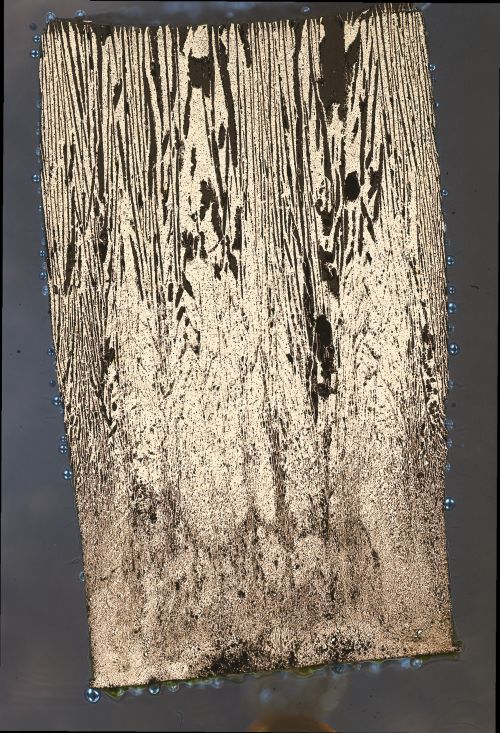

Figure 2. Vertical cross-section of an iron foam created by freeze-casting iron oxide, sublimating the ice crystals, reducing the oxide in hydrogen, and sintering. Freezing direction is from the bottom-up. |

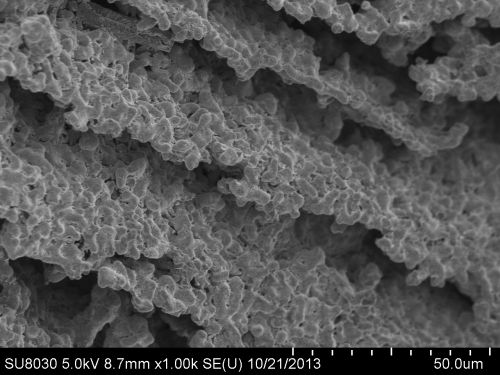

Figure 3. SEM micrograph showing the high surface area and microporosity of the scaffold walls created through freeze-casting and reduction |

Related Publications

- Xu, N., Li, X., Zhao, X., Goodenough, J.B., Huang, K., 2011. A novel solid oxide redox flow battery for grid energy storage. Energy & Environmental Science 4, 4942-4946.

- Deville, S., 2008. Freeze-Casting of Porous Ceramics: A Review of Current Achievements and Issues. Advanced Engineering Materials 10, 155-169.