NiTi Foams by Transient Liquid Phase Sintering

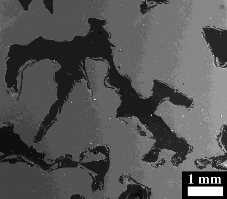

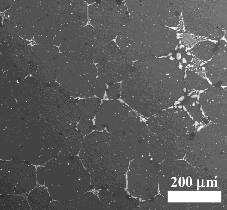

FIGURE 1: (a) Micrographs of porous NiTi created with 0.25 mm diameter Nb wires, which created a liquid eutectic leaving behind elongated pores, and (b) wicked into the matrix to densify the NiTi powders. (1)

*Dr. Catherine Tupper and *Dr. Ampika Bansiddhi

Porous NiTi is produced by sintering pre-alloyed NiTi powders with NaCl powders which are removed to create 40-60 vol.% macro-pores which are open to the surface, blocky in shape and 100-400 μm in size. The micro-porosity present between the NiTi powders is infiltrated by an in-situ created NiTi-Nb eutectic liquid which, after solidification, densifies the NiTi powders into dense struts. This new method (1) allows for separate control of the macro-porous structure and the densification and composition of the NiTi struts.

A related new method (2) uses NiTi powder compacts containing Nb wires as spaceholder. When are heated above 1170oC, each Nb wire reacts with adjacent NiTi powders to form a eutectic liquid which wicks into the space between the remaining NiTi powders. This creates a macro-pore at the location of the Nb wire while eliminating the microporosity between NiTi powders which is filled with a NiTi/Nb eutectic phase after solidification. This novel method produces - in a single step and without applied pressure - dense NiTi with elongated pores suitable for shape-memory or superelastic applications such as bone implants, dampeners and actuators.

Relevant Publications

- A. Bansiddhi, D.C. Dunand, "Niobium Wires as Space Holder and Sintering Aid for Porous NiTi", Advanced Engineering Materials, in print

- A. Bansiddhi, D.C. Dunand "Processing of NiTi Foams by Transient Liquid Phase Sintering", Journal of Materials Engineering and Performance, in print

Replication of micro-channels in NiTi

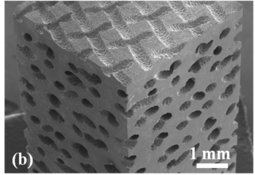

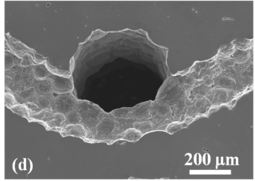

FIGURE 1: Scanning electron micrographs of compression specimens of NiTi with 34% replicated micro-channels

Catherine Tupper, Antoine Emery and Anselm Neurohr

A new process is developed for fabricating arrays of micro-channels in shape-memory NiTi for bone implant applications, with a tailorable internal architecture expected to improve biomechanical compatibility and osseointegration (1). Porosity is created by electrochemical dissolution of parallel layers of steel wire meshes embedded within a NiTi matrix during hot pressing of NiTi powders. The resulting NiTi structures exhibit parallel layers of orthogonally interconnected micro-channels (350-400 µm diameter, 24-34 vol.% fraction) that exactly replicate the steel meshes. These NiTi structures with replicated networks of micro-channels have excellent potential as bone implants and scaffolds given: (i) the versatility in channel size, shape, fraction and spatial arrangement; (ii) their low stiffness (15-26 GPa), close to 12-17 GPa for cortical bone; (iii) their high compressive strength (420-600 MPa at 8-9% strain); and (iv) their excellent compressive strain recovery (91-94% of an applied strain of 6%) by a combination of elasticity, superelasticity and the shape-memory effect.

Relevant Publications

- A.J. Neurohr, D.C. Dunand, “Shape-Memory NiTi with Two-Dimensional Networks of Micro-Channels”, Acta Biomaterialia, in print.