Al-Cu Creep Resistant Alloys

Dr. Jovid Rakhmonov and Dr. Christoph Kenel, in collaboration with Dr. Amit Shyam, ORNL

Al-Cu alloys gain significant strength from nanosized, metastable θ' (Al2Cu) precipitates forming during aging heat treatments. However, upon exposure above 200 °C, these precipitates coarsen rapidly and eventually transform into the undesirable, equilibrium ? phase, resulting in a significant loss in alloy strength. Recent studies have shown that θ' precipitates become resistant to coarsening and to θ- transformation, during prolonged exposure at 300-350 °C, when the alloy contains microadditions of transition metals, such as Zr and Mn [1, 2]. A series of high-temperature-resistant Al-Cu-Mn-Zr alloys have been developed at ORNL, with Mn and Zr segregating to θ' interfaces (Figs. 1 and 2), thus enhancing the stability of this phase through the combination of thermodynamic and kinetic factors [3]. Moreover, increasing Cu concentration beyond its maximum solubility in α-Al contributes positively to the hot-tearing resistance of these Al-Cu-Mn-Zr alloys [4]. A combination of enhanced high-temperature strength and hot-tearing resistance makes these alloys promising candidates for high-temperature powertrain components, such as cylinder heads.

In this work, we study the role of intradendritic θ' and L12 (Al3Zr) precipitates, as well as grain-boundary θ particles, on the creep resistance at 300 ºC of a series Al-Cu-Mn-Zr alloys, deformed either in tension or in compression. This study also sheds light on the stability of the θ' phase under combined elevated temperature and applied stress.

Funding support

- Oak Ridge National Laboratory

Related Publications

- J.D. Poplawsky, B.K. Milligan, L.F. Allard, D. Shin, P. Shower, M.F. Chisholm, A. Shyam, The synergistic role of Mn and Zr/Ti in producing ?'/L12 co-precipitates in Al-Cu alloys, Acta Mater. 194 (2020) 577-586.

- J. Rakhmonov, K. Liu, L. Pan, F. Breton, X.G. Chen, Enhanced mechanical properties of high-temperature-resistant Al-Cu cast alloy by microalloying with Mg, J. Alloys Compd. 827 (2020) 154305.

- S. Bahl, L. Xiong, L.F. Allard, R.A. Michi, J.D. Poplawsky, A.C. Chuang, D. Singh, T.R. Watkins, D. Shin, J.A. Haynes, A. Shyam, Aging behavior and strengthening mechanisms of coarsening resistant metastable ?' precipitates in an Al-Cu alloy, Mater Design 198 (2021) 109378.

- A.S. Sabau, B.K. Milligan, S. Mirmiran, C. Glaspie, A. Shyam, J.A. Haynes, A.F. Rodriguez, J. Gonzalez Villarreal, J. Talamantes, Grain Refinement Effect on the Hot-Tearing Resistance of Higher-Temperature Al-Cu-Mn-Zr Alloys, Metals 10(4) (2020).

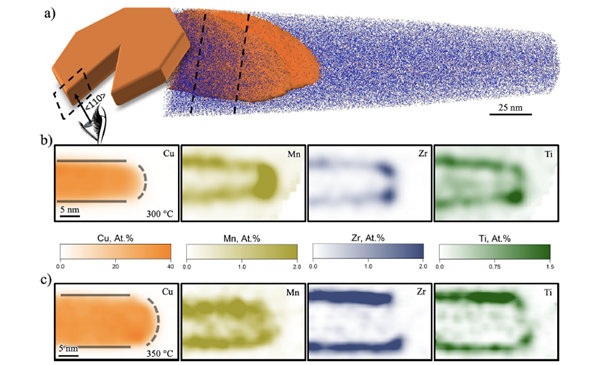

Fig. 1 (from Ref. [1]). (a) A schematic of the viewing direction for the 2D contour plots along with an APT atom map of the Al-Cu-Mn-Zr alloy exposed to 300 °C for 2100 h containing a ?' precipitate with Al and Cu ions displayed as blue and orange dots, respectively, and a 10 at.% Cu iso- concentration surface. (b) An extracted ROI from the dataset shown in (a) with the axes redefined such that the precipitate is viewed in its cross section in the [110] direction. (c) 2D contour plots of a precipitate cross section for an Al-Cu-Mn-Zr alloy exposed to 350 °C for 2000 h. The coherent and semi- coherent interfaces are marked by solid and dotted lines in the Cu profiles, respectively.

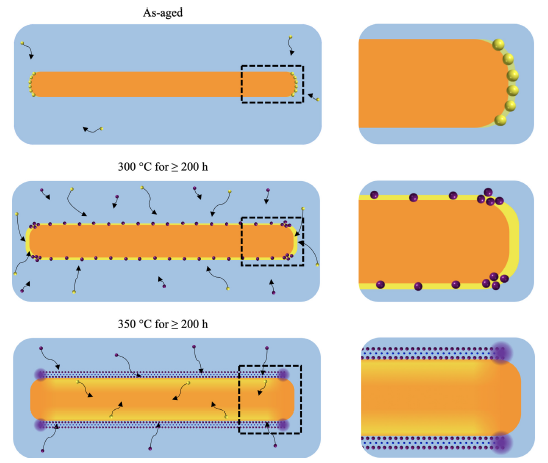

Fig. 2 (from Ref. [1]). A schematic showing the segregation behavior of Mn (yellow) and Zr/Ti (purple) to at the interface between Al matrix (blue) and ?' precipitate (orange) in Al-Cu-Mn-Zr alloys. For the as-aged state, only Mn is effectively diffusing and segregating to the semi-coherent interface. After an extended 300 °C heat treatment, Mn covers the entire precipitate, while Zr/Ti only segregates to the coherent interface. After an extended 350 °C heat treatment, Al3(ZrxTi1-x) begins to form on the coherent interface as Mn infiltrates the precipitate core with higher Mn content closer to the interface.