Microstructural Evolution in Freeze-Cast Materials

Kristen Scotti, Ming Chen, and Jesse Ji

co-advised with Prof. Peter Voorhees

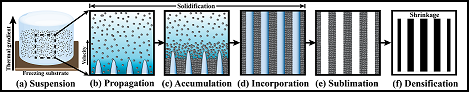

Directional freeze-casting is a solidification technique that produces materials with complex, three-dimensional pore structures. The directional freeze-casting process is depicted in Fig. 1. First, (a) a suspension of particles is placed into a mold. The base of the mold (typically thermally conductive) is cooled, promoting (b) nucleation and directional propagation of a solidification front. As solidification progresses, rejected particles are concentrated within interdendritic space (c). Once solidification is complete, the solidified fluid is (d) removed via sublimation, and (e) the resulting scaffold is sintered to densify particle-packed walls. The underlying principles of the freeze-casting technique are not strongly dependent on material type, but rather the physical nature of the solidification process itself. Freeze-casting has been utilized as a processing method for porous ceramics, polymers, and metals. A major advantage of the technique is the ability to adjust microstructural properties by manipulating solidification conditions. In turn, this offers the ability to tailor mechanical and physical properties to suit desired applications, further enhancing the cross-cutting nature of the freeze-casting technology.

Although freeze-casting has the potential to produce application-specific microstructures, solidification conditions must be properly controlled for precise microstructural control to be achieved. The underlying principles that govern microstructure formation during solidification are not well understood, making a priori predictions difficult. Major impediments to the study of these processes are the gravity-driven convection and sedimentation that arise in the liquid due to the combination of temperature and particle and/or additive (e.g., binders, dispersants) density/concentration gradients. Microgravity investigation of the freeze-casting technique will provide a better fundamental understanding of solidification behavior which will allow for the development of improved processing techniques and predictive control of materials design, applicable to a wide variety of applications for optimized material fabrication on Earth, on planetary surfaces, and in orbit.

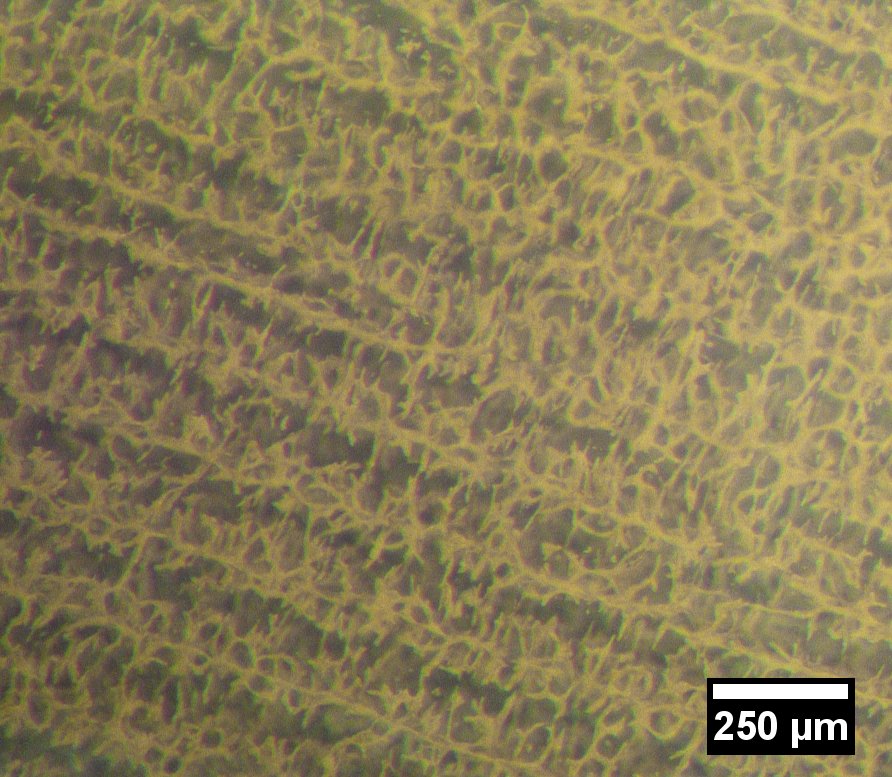

As part of NASA's Materials Lab Open Science Campaign, directional solidification experiments will be conducted on the International Space Station and freeze-casted samples will be sent back to Northwestern University for microstructural investigation. The aim of this work is to produce benchmark data necessary to advance the freeze-casting technology for both terrestrial and space-based materials processing, including producing data applicable for testing three existing freeze-casting models. We are currently testing candidate suspension systems for further ISS testing; Fig. 2 shows an optical micrograph of a directionally solidified thin sample employing one of our candidate systems: CuO nanoparticles suspended in succinonitrile.

Fig. 1. Diagram illustrating the steps in the freeze-casting process, including: (a-d) solidification, (e) sublimation, and (f) densification.

Fig. 2. Optical micrograph showing the dendritic microstructure of a directionally solidified succinonitrile/CuO suspension thin sample.

Related Publications

- Scotti, K.L. & Dunand, D.C. (2017). Freeze Casting: A review of processing, microstructure and properties via the open data repository, FreezeCasting.net. Submitted to: Progress in Materials Science.

- Scotti, K.L., Northard, E.E., Plunk, A., Tappan, B.C., & Dunand, D.C. (2017). Directional solidification of aqueous TiO2 suspensions under reduced gravity. Acta Materialia, 124, 608-619.

- Scotti, K. L., Kearney, L. G., Burns, J., Ocana, M., Duros, L., Shelhamer, A., & Dunand, D. C. (2019). The effect of solidification direction with respect to gravity on ice-templated TiO2 microstructures. Journal of the European Ceramic Society, 39(10), 3180-3193.

Funding Support

- NASA Physical Sciences Research Program