NiTi-based Foams

NiTi Foams by Transient Liquid Phase Sintering

*Dr. Catherine Tupper and *Dr. Ampika Bansiddhi

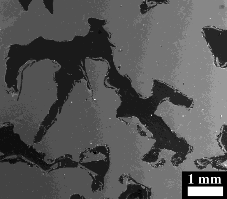

Porous NiTi is produced by sintering pre-alloyed NiTi powders with NaCl powders which are removed to create 40-60 vol.% macro-pores which are open to the surface, blocky in shape and 100-400 µm in size. The micro-porosity present between the NiTi powders is infiltrated by an in-situ created NiTi-Nb eutectic liquid which, after solidification, densifies the NiTi powders into dense struts. This new method (1) allows for separate control of the macro-porous structure and the densification and composition of the NiTi struts.

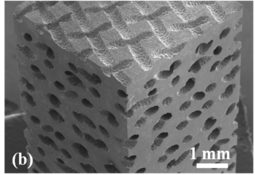

A related new method (2) uses NiTi powder compacts containing Nb wires as spaceholder. When are heated above 1170oC, each Nb wire reacts with adjacent NiTi powders to form a eutectic liquid which wicks into the space between the remaining NiTi powders. This creates a macro-pore at the location of the Nb wire while eliminating the microporosity between NiTi powders which is filled with a NiTi/Nb eutectic phase after solidification. This novel method produces - in a single step and without applied pressure - dense NiTi with elongated pores suitable for shape-memory or superelastic applications such as bone implants, dampeners and actuators.

Current investigations include utilization of platforms that provide for longer periods of microgravity. In partnership with the University of Illinois, Urbana-Champaign and Bradley University, directional solidification experiments will be conducted on a CubeSat (a small satellite that orbits Earth); the satellite is scheduled to launch with NASA’s CubeSat Launch Initiative in late 2018. Subsequent investigation will include a “sample-return” mission that will take place on the International Space Station (ISS) through NASA’s Materials Lab Open Science campaign, where suspensions will be solidified on the ISS and returned to Earth for subsequent processing, including microstructural characterization.

FIGURE 1: (a) Micrographs of porous NiTi created with 0.25 mm diameter Nb wires, which created a liquid eutectic leaving behind elongated pores, and (b) wicked into the matrix to densify the NiTi powders. (1)

Related Publications

- Bansiddhi, A., & Dunand, D. C. (2011). Niobium wires as space holder and sintering aid for porous NiTi. Advanced Engineering Materials, 13(4), 301-305.

- Bansiddhi, A., & Dunand, D. C. (2011). Processing of NiTi foams by transient liquid phase sintering. Journal of materials engineering and performance, 20(4-5), 511-516.